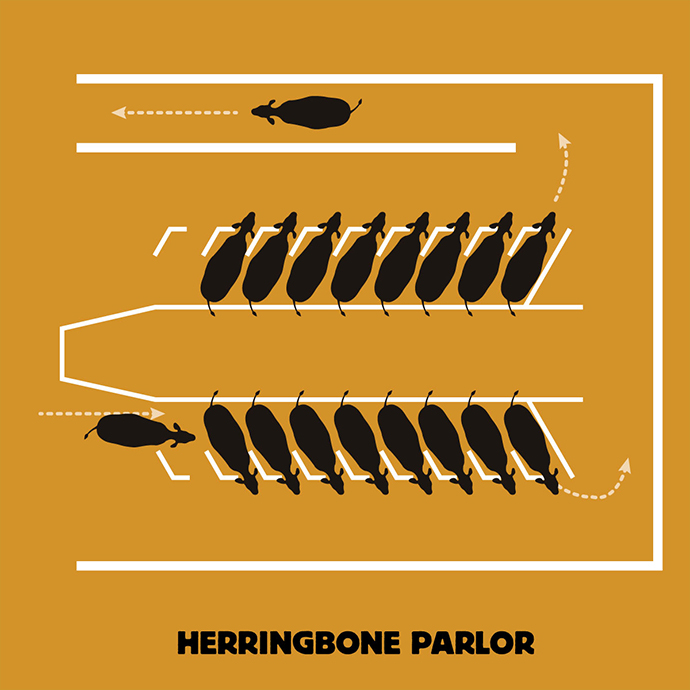

We work to configure the best cow comfort cow flow operator comfort shed layout and pathways from the simplest to the most complex of parlour plans. Herringbones Tactics such as minimising the time waiting for cows to exit by early release of the head gate improves parlour efficiency Clusters managed per operator is determined by work routine and milking duration of the slowest milking cow Applying a maximum milking time MaxT increases cow throughput Rotaries.

What is a rotary milking Parlour.

. There are a smaller number of robotic sheds emerging. The number of cows milked per hour. Let GEA support you.

All these animals need to be housed in separate sheds and the provision in the layout has to be made accordingly. From initial design to completed build we can manage your whole project from start to finish including yards plumbing etc. They come into the parlour and line up between each fishbone creating two rows of cows.

Recent data manually entered by farmers on the Milksmart website milksmartconz and electronic data obtained in the 201011 season from 80 high tech rotary dairies56. In Sharps system the cows line up on either side of a central pit where the operator can put on and take off the milking cups without having to bend down. Each dairy farm has a milking shed where the cows are milked by machines.

The Herringbone Dairy is still the most widely used dairy style in Australia. One of the most common milk sheds the herringbone shed has a central sunken pit and a raised platform on each side where the cows stand whilst being milked. In Sharps system the cows line up on either side of a central pit where the operator can put on and take off the milking cups without having to bend down.

Individual cow identification for Herringbone sheds enables fast easy accurate in-shed animal management. Hot-dip galvanised steel structure. Now one person could milk 75 cows per hour and the maximum practical herd size for a family farm increased from 100 to 400 plus.

30 60 or 70 milking stalls. They are heavy duty robust parlour construction that comes with modular design for speedy installation. In the old walk-through sheds each cow was milked at its own speed.

In a rotary parlour the cow walks onto a rotating platform. The main variations in a Herringbone Dairy are Swing Over Double Up and Walk Through with. The data presented in Figure 4 pg 10 are from two sources.

There are a range of widths and other critical dimensions for the herringbone the 2 6 and the side-by-side parlours and these are shown below. The herringbone and rotary dairy differ in design but how do they differ in their ability to milk cows. Dairy Parlour Design and Construction.

Systems by actually milking in each design rather than simply observing the parlour. Herringbone Milking Parlour is ideal milking parlour systems for dairy farms that are positioned in the middle between two aisles with room for cows. Set alerts make notes and create groups while in the shed or.

For small and medium size operations the system when well-designed can provide excellent animal throughput operator and animal comfort and can integrate with many levels of automation. Planning - It is important to work closely with your milking equipment supplier to develop a plan but leave it up to the supplier to look after equipment placement and design details. So it almost becomes secondary whether you choose milking from a GEA herringbone milking parlor a parallel milking parlor side-by-side or a tandem milking parlor.

Apart from the animal sheds the certain other ancillary buildingsstructures are also. Up to 24 cash back Milking Shed designs Y10 Agriculture Rotary Shed Cups on here Cups off here Rotary Shed Comment Some float on water. NEW ROTARY AND HERRINGBONE DAIRY SHEDS We specialise in new herringbone and rotary dairy shed builds on the West Coast.

Making sure cows are comfortable while entering and exiting the dairy as well as during milking will have big benefits for cow flow and efficiency. In the old walk-through sheds each cow was milked at its own speed. The two common types of milking sheds parlours in Australia are herringbone and rotary sheds.

There are tales of the odd herringbone-style shed having popped up before this time in Australia but these were isolated and unlike Sharps design they didnt cause a sea change in the dairy industry. The milk is held in a vat before it is collected each day and taken to the factory by a milk tanker. Quick group changes and precise positioning let you achieve high work efficiency with the herringbone milking parlor.

Stainless steel pit edge protection. Small modification to design can significantly improve cow flow without costing too much. Milklines herringbone milking parlours are available in different configurations - 30 60 or 70 side milking - and with different options to best suit your needs.

In 1952 Ron Sharp a Waikato dairy farmer developed the herringbone shed design which transformed the milking process. GEAs DairyParlor line features a variety of successful formulas you can benefit from. In 1952 Ron Sharp a Waikato dairy farmer developed the herringbone shed design which transformed the milking process.

DairyParlor P7400 - Herringbone Parlors. Configure your parlour Download datasheet. Over 40 years of continuous improvement of our designs through innovation client feedback and new compliance requirements ensure you the client are getting the best value for your money.

Don Chapman Waikato is a licensee for Chapman Dairy Ltd who have been designing and building milking parlours since 1967. Building blocks for farm security When designing a facility bio-security is our top priority therefore we examine all options for milk transport manure handling and all other traffic. Wide alleys allow cows to enter the milking stall stress-free and stand comfortably and relaxed for better milking.

Design your milking centre around the type and size of milking parlour you have selected Figure 1. Know which cow is in which bail so you can be sure of what treatments alerts and withholds are against them. These are guidelines only so consult milking machine manufacturers to get the exact dimensions for their machines.

Cows are identified while they are milking where they are milking. Animal-friendly stall design optimal cow positioning and a fast as well as gentle milking process have a positive effect on udder health. Modern parlour designs have been developed to cater for increased herd size and incorporate automation in the herringbone auto-tandem and rotary.

The two common types of milking sheds parlours in Australia are herringbone and rotary sheds. The various categories of dairy animals may be formed such as milking cows dry and pregnant cows down-calvers bulls heifers and the calves. We are proud to be locally owned and operated faithfully serving our customers for many years.

Most expensive Hard to extend Disadvantages Lowest labour need. Advantages Herringbone Herringbone Herringbone Herringbone Comment Named after a Herring fish backbone.

Buildings Focus Milking 300 Cows In A 50 Unit Rotary Parlour In Co Galway Agriland Ie

Herringbone Dairy Shed Rural Construction Calder Stewart

4 Modern Milking Parlor Designs Dairy Discovery Zone

Herringbone Milking Systems Read Industrial Ltd

Herringbone Bail And Pit Design Dairynz

Using A Herringbone Dairy Shed Farm Buildings Te Ara Encyclopedia Of New Zealand

The Changing Face Of The Nz Cow Shed Number 8 Network

Farm Structures Ch10 Animal Housing Cattle Housing Milking Parlour

0 comments

Post a Comment